RHIZOM

2020Nachhaltiges und wandelbares Bausystem im ruralen Kontext.

Bachelor Arbeit

Mentors: Prof. Birgit Weller and Prof. Sebastian Feucht.

RHIZOM consists of a set of prefabricated elements that can be fast and easily assembled without the need for a building site. Once assembled, the small to large residential units, offices or common spaces can be dismantled into their individual parts and reassembled at another location thanks to their modularity. A thoroughly effective, sustainable and adaptable solution to counteract the ever-increasing housing shortage, especially in the Berlin-Brandenburg region. This construction system is designed to meet the needs of several target groups: from individuals who need affordable accommodation, families without children who are looking for a specific type of housing, to young entrepreneurs who need an aesthetically attractive and cost-saving solution for their new office outside the city.The units can be configured according to specific needs, requirements and economic capacity. They are organized on a two-dimensional grid and can appear in simple or in more complex configuration. The addition of a second floor is also possible. Prefabrication, which has established itself as an advantageous construction method in recent years, also enables an efficient transport logistics, fast and precise assembly and dismantling. Designed to be integrated into rural spaces, Rhizom ties in both formally and constructively with the german tradition of timber framing houses and can be classified in both the mobile and temporary architectural movement. The Project was supervised by Prof. Birgit Weller und Prof. Sebastian Feucht.

MATERIALS

Rhizom is completely made of environmentally friendly materials: Glulam for the framework, CLT for walls and floors, metal or straw for the roof, natural stone blocks for the foundations, gravel for the outside floors. However, there is no shortage of more conventional materials such as glass and carbonate.

Glulam is a type of structural engineered wood product constituted by layers of dimensional lumber bonded together with durable, moisture-resistant structural adhesives.

Cross-laminated timber ia a sub-category of engineered wood. CLT is a wood panel product made from gluing together layers of solid-sawn lumber.

Each layer of boards is usually oriented perpendicular to adjacent layers and glued on the wide faces of each board, usually in a symmetric way so that the outer layers have the same orientation.

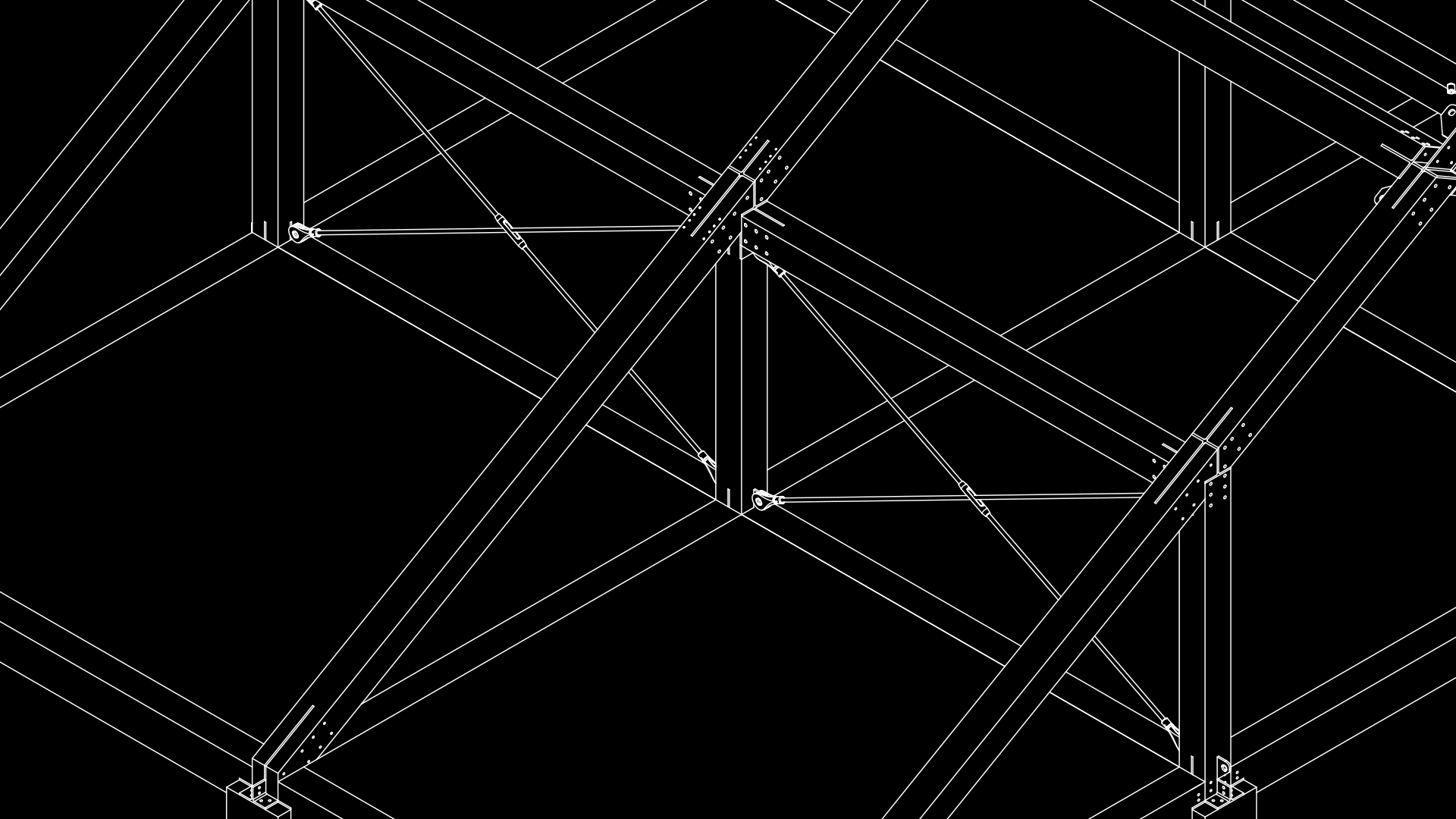

BRACING

Dissipate tension and compression forces

The bracing ensures the stability of the structure. A strut is a structural element that often runs diagonally and is primarily used to transfer tension and compression forces.

In timber framing construction, struts are part of the crossing and serve to stiffen the overall construction.

The anchor points are either on the connecting plates, which are embbed into the rafters, or in the node connecting elements. This makes possible to orient the bracing on two different axes. Such a system greatly increases the freedom degree in designing the respective configuration.

POST

Posts for partition and supporting walls

The inner and outer posts have been designed to install supporting and partitions walls in the framework. Since they are affected by the forces of a single axis, just like the individual elements of the framework, the inner posts are also made of Glulam.

Three types of posts have been designed to ensure maximum flexibility for different configurations:

1 - for glass panes

2 - for CLT walls

3 - for carbonate multi-wall sheets

The inner posts consist of the following main elements:

1 - The Glulam post

2 - The mounting steel jig (slots)

3 - The mounting boards

4 - Tracks for glass panes, carbonates multiwall sheets and CLT walls.

There is no difference between the upper and the bottom part of the post, they have symmetrical design (which make their vertical arrangement easier). Although the sturdiness of the posts is partly reduced by subtracting the material (saving on slots), it is recovered by the same slots. The slots are made of solid structural steel and statically complement the material that has been removed. The fastening screws must be secured with a special tool.

NODES

The concept is based on modular, add-on principles. The nodes are the main intersections of the construction, where the metal plate (nodes) is fastened to the Glulam elements with screws and bolts. During assembly, the nodes are first inserted into the milled slots of the post. Then the connecting plates of the beams are integrated and the whole block is fixed. The procedure is repeated for the beams and then for the rafters. The procedure for dismantling is simply the other way round. Once fully fastened, all elements and the connecting plates disappear into the milled slots of the Glulam elements. All that remains visible are the edges of the connectors and the cut-outs in which the bolts find their place. The nodes are not only meant as fastening elements for the beams, the rafters, the beam layers or ridge. Additional plates provide the necessary anchor points for the roof, for the cladding elements and for the external rod system for greening the façade.